Increasing automation helps improve productivity and resource utilisation

The Company

NS Engineering Ltd was established in Coalville in 1986 as a subcontract engineering firm. Trading as NS Engineering Solutions they specialise in the high precision engineering and the manufacture of component parts for the construction, mining and rail sectors.

What they do

NS Engineering Solutions pride themselves on being problem solvers - helping clients overcome difficult challenges and maximise their efficiency through new design and engineering processes.

Based in Leicestershire, their factory floor consists of a range of machinery including 3 axis CNC lathes and 3 & 4 axis machining centres, all staffed by skilled professionals who pride themselves on maintaining high standards and a work ethic that puts safety, speed and quality above all else.

They offer a complete CNC machining, fabrication and finishing service. Their clients come from the Midlands and further afield and a wide variety of industries including but not limited to, the quarrying, brick, rail, pump and automotive industries along with the Oil and Gas, mining and power generation sectors. They provide a complete service from initial drawings to delivery.

The Challenge

The company needed to improve their productivity, resource utilisation, on-time delivery and component quality within their milling zone. To do this they needed to replace their older Oerlikon FB2V milling machine with a new CNC milling machine. They were looking for a machine with more automation then their current equipment as this would allow them to change the working shift patterns. They hoped that this would give them:

- 5% more machine time for the same cost

- 25% increase in productivity on a more capable machine

- 18% increase in utilisation through shift changes and machine automation

- Better-quality components on a more accurate machine

- Increased chance of on-time delivery through production flexibility.

Machines of this type are expensive and require a significant investment.

The Solution

- Grant funding

NS Engineering Ltd applied to ERDF SPRING for grant funding to assist with the purchase of a new CNC milling machine.

The Outcome

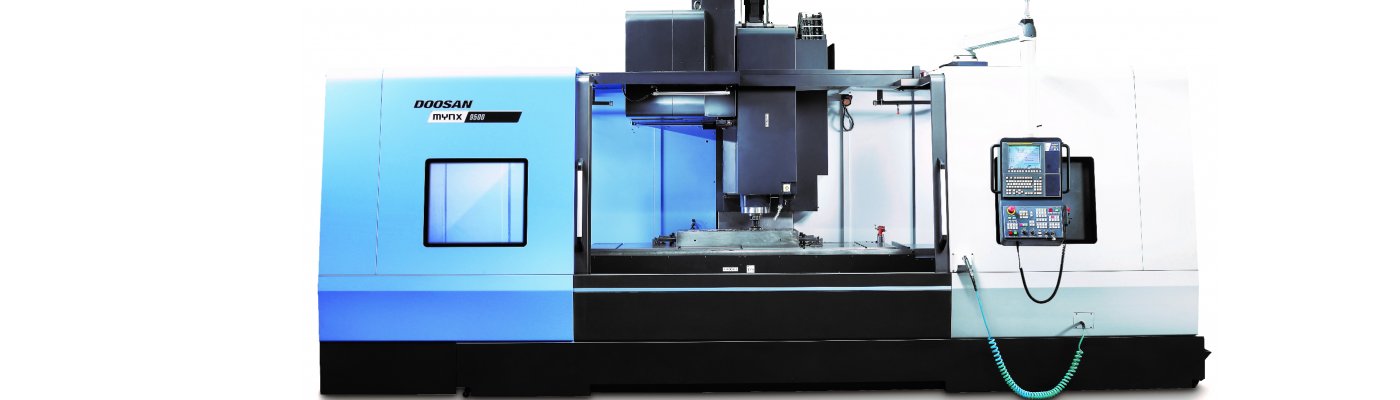

The company used the grant to purchase a Doosan Mynx 9500 CNC milling machine which would not only allow them to realise the target benefits but would also allow them to machine a current component 25% faster than at present. This is due to the x axis travel of 2500mm on this machine. Without the financial help of the grant they wouldn’t have been able to justify purchasing this longer x axis (2500mm) model.

Paul Harper, Managing Director, NS Engineering Ltd

"The new Doosan Mynx 9500 increases our productivity, improves our flexibility to customers’ needs and improves our component quality. It also offers production cover and further setup efficiencies for an existing Doosan Mynx 7500 CNC milling machine which sits in the same zone. This means we can very quickly move components between the two machines if production and on-time delivery demand’s it without needing to make many changes to the CNC program. This is a significant investment in manufacturing for us and one will would not of been able to make without the help of the funding organised through the iNet team".

https://www.the-inet.org.uk/case-studies/NS-Engineering/

17 Jan 2020

Contact details

Name:Paul Harper

Organisation:NS Engineering Solutions

Address:Units 23-24

Snibston Drive

Coalville

Leicestershire

LE67 3NQ

Telephone:01530 835400

Email:paul@nsengineering.co.uk

Website:http://www.nsengineering.co.uk

Twitter:@NS_Eng

LinkedIn:https://www.linkedin.com/company/ns-engineering-solutions-ltd